Well this is going to be a *slight* departure.

I have been asked to contribute to an article (see here) on the 30th Anniversary of the ZX Spectrum by a local paper and this triggered a trip down memory lane (not to mention a wasted lunchtime looking through the Spectrum archive at World of Spectrum).

Ironically I never actually owned a Spectrum having had parents who brought into the whole "BBC is educational, Spectrum and Commodore are for Games". I was lucky(?) in that I had a group of friends one of which had a Commodore 64 (let's call him "Ian"), the other started with a Spectrum 48 (let's call him "Matt"), then the 48+ which had a "proper keyboard", then went on to a 128+2 and finally stuck with the Spectrum right into it's death throes with the SAM Coupe* (yes, I know *technically* the QL should be in there somewhere but I don't think I ever met anyone who owned one of them!).

On the plus side this always meant that at least two of us could agree that the other's machine wasn't the best! The hours (and hours and hours) we wasted arguing over that one!

As you can imagine, 30 years ago, the games could be described at best as "primitive" by todays standard and while Ian, with his Commodore 64, was blessed with two joystick ports AND two joysticks to plug into them I was stuck with my BBC and a single joystick which worked so rarely that it was just quicker to use the keyboard and finally Matt had a special expansion plug in (Interface II?) at the back of his Spectrum for a couple of joysticks but it was a little loose so occasionally you would knock it and the entire machine would just spontaneously die. Fun times.

Nevertheless my fondest computer-related memories of that time feature some of the classic games on the Spectrum. Whilst the graphics were poor some of the games are absolute classics you could play for hours on. Here's some of the ones I can remember (in no particular order);

Cobra (Ocean Software Ltd)

A sideways scrolling shoot-em-up based (very very loosely!) on the Sylvester Stallone movie of the same name. This is one of the rare examples where the simplicity of the Spectrum graphics actually made for a more enjoyable game than the graphically superior version on the Commodore 64. Luckily this game is available on the World of Spectrum website (click here).

Twin Kingdom Valley (Bug-Byte)

Now this one is a real classic but I'm guessing it's not going to be to everyone's taste! It's a text (ok, there's a few graphics) adventure game. The reason I really liked this one is that the world is populated with Elves, A Giant, and an Innkeeper who were all your friends, and Gorillas, Dragons, Castle Guards, Trolls, Witches, Sand Lurkers, etc who definitely weren't.

Your aim was to collect all the treasure and leave it in your hut (pictured below) but the bit of the game I really enjoyed was helping the Elves and the Giant rid the world of all the "evil" people (you could arm them and they'd help you in a fight). Excellent game and, if memory serves (it may now) D, N, N, N, W, W, S will get you from the metal grate to the cliff edge - if only I'd had that kind of recall during my exams!

Again this title is available from World of Spectrum - click here.

Target Renegade (Imagine Software Ltd)

A successor to the incredibly popular Renegade but introducing multi-player. An absolutely fantastic beat-em-up game where you went through several levels defeating adversaries in order to get rid of the "end of level baddies".

The Spectrum keyboard was pretty small so as you can imagine it would become quick complicated for two people to hammer way on the keyboard at the same time - add in to that the game would actually multi-load (when you completed a level you'd need to wait 2-3 minutes to continue and when you died you had to rewind the tape!) and you'd think no-one would enjoy it but we literally spent entire weeks getting through it (which we did eventually!). Fantastic game!

Here's the link on World of Spectrum.

You might also want to try out the original Renegade here.

Bubble Bobble (Firebird Software Ltd)

A really nice arcade conversion that massively benefited from allowing two players to play simultaneously. You could bounce around popping monsters on this one for ages, sadly at higher levels it just became a complete nightmare to play so while we used to play this one for absolutely ages it's actually one of the few I've not been inclined to play again via an Emulator.

Still, great memories.

And it's available here on World of Spectrum.

And finally (otherwise I'll be here all night);

R-Type (Electric Dreams Software)

Possibly the best (well, with Salamander) shoot-em-up ever. You could pick up power-ups as you went along and there were end of level baddies. Does it get any better than that?!

Sadly while World of Spectrum has a page for this game (here) the makers have specifically denied them the right to distribute it. Still it's good to know that the game has been saved for posterity, even though until the Copyright formally expires I won't be able to access it!

Well that's it, just a simple pick of a few games from my youth. If you're interested in finding out more then I'd recommend browsing the World of Spectrum Archive, especially the Best Games page.

In 30 years I wonder what my kids kids will be playing?!

*- Whereas my progression from BBC directly to A3000 (an Acorn Archimedes) then to a Risc-PC before moving on to the more-familiar PC (and now a MAC). See? It's not just Jeremy Clarkson who can waffle on about old cars - computer geeks can do it too!

This blog is recording things I think will be useful. Generally these are IT-solutions but I also touch on other issues as well as-and-when they occur to me.

Sunday, September 30, 2012

Saturday, September 29, 2012

Using iOS 6 Apple Maps "Report A Problem" Feature

As I'm sure you'll be aware Apple are experiencing a few problems with their brand new Apple Maps application for iOS 6 (see here for CEO Tim Cooks' public apology). One of the features of the new Maps application is a "Report A Problem" link, you can use this to report issues to Apple for them to fix - clearly they'll have a lot to do.

Here's how to report an issue;

Here's how to report an issue;

- First of all go to the location in Apple Maps which shows the problem you'd like to report;

- Then click on the bottom-right "page" bit to see the settings;

- Just above the "Print" button in *very* faint type (makes you wonder if they intended people to spot it doesn't it?!) there is a "Report a Problem" link. Click on this.

- Now you pick the type of issue you want to report. Here's a tip; if you want your issue dealt with quickly (and that's a relative term!) don't select "My problem isn't listed" - I don't know what black hone that vanishes into but don't expect anyone to get back to you soon! For the sake of this example I'm going to pick "Location is missing" (as it is!);

- At the top of the screen it says "Drag the pin to the correct location". Do that and then when you're done click "Next" at the top right;

- Now you can enter as much details as you can for the item you're reporting as being missing. I'm reporting "Bar Hill Tesco" and I've picked the details of their website (I've even included the link so Apple can check it). Then click "Next";

- Now, after you're spent all that time typing stuff in, it tells you that the map information and problem you've entered will be reported to Apple if you click "OK". You could just click "Cancel" if you want to have wasted your time.

Friday, September 28, 2012

Apple Maps Comes To Bar Hill!

As I'm sure you're aware Apple have updated their iOS devices (iPad, iPhone, iPod) with iOS 6 which replaces the existing Google Maps with *new* Apple Maps which includes Turn-By-Turn navigation as well as a 3D view.

Sadly the new Maps application is not quite up to the standard of Google Maps (in much the same way as an ant is not quite up to the height of a giraffe).

Looking at Bar Hill Tesco is a good example of where this has not quite worked ... The map at the right shows Tesco Car Park with access both to Gladeside and Viking Way (neither of which exists), and a surprising loop in the car park.

If nothing else pondering these anomalies with give the people trapped in the one-way system that the Petrol Station has suddenly turned into something to think about!

There are numerous other issues; "Long Stanton Road" as an example of a typo (should be "Longstanton Road"), and half the businesses are missing including Tesco, the Parish Council Officers, the Church, etc.

I have reported several of these, but fixing everything is going to be a *huge* job and is way beyond anything that Apple have planned - Google Maps after all didn't get anywhere near as good as it is now overnight! It's just a shame this half-finished product is being forced onto people in it's current state.

So what should Apple do? (let's just pretend they are taking advice from random bloggers!) I've mentioned before in various blogs the open-source mapping information provided by www.openstreetmap.org seems to be a viable alternative. For example;

| OpenStreetMap.org - Bar Hill, Cambridgeshire |

I'd suggest to Apple that rather than trying to build their own mapping database - which will take years - or buying one of the not-as-good-as-Google mapping companies out there to get access to their data why not work with OpenStreetMap and provide some funding for the project and use open source mapping data? Give it all away free and people will help you build it.

Anyway, here's hoping they do something soon!

Labels:

apple,

apple maps,

bar hill cambridgeshire uk,

google,

google maps,

iOS

Monday, September 24, 2012

SSRS: Scheduling A Report With 2008R2 (In SharePoint Integrated Mode)

In an ideal world you'd go to a report, enter your parameters, run the report, and a few seconds later you'd have all your data in the format you need. Unfortunately whilst going to the report and entering the parameters are (usually!) easy, the "few seconds" can quickly stretch to "a few minutes" and beyond before you get your data - particularly with some of the more complex GL-based reports.

As most reporting is clyclical (month end, year end, financial year, monthly sales, weekly orders, etc) it's possible to predict the reports you'll need for a particular period and it's possible, using Reporting Services and SharePoint to scheduled the reports to run when you know you'll need them.

The first step is to go to your report;

At the top-left of the web page is a "Actions" drop down. Select this and choose the "Subscribe" option. If you don't have a subscribe option then you probably need to contact whoever administers your server to see why not; there really isn't any reason why users who run reports shouldn't be able to schedule them to run out-of-office hours.

When you select "Subscribe" you'll be directed to the following web page to select the options for the report;

This page allows you to choose how you want to receive the report. By email is probably the simplest way (and is the default). The available options are;

*- you'll notice, if you squint really hard at the "Shared Schedule" option that we (OK, I) made a mistake when setting these up. The point of shared schedules should be to increase the flexibility of system administrators to juggle the jobs around but make sure they are still available when needed. "Monthly (1st) @ 7am)" isn't exactly flexible, what I should have created is "Monthly (1st) before 8:30" so I'd be able to move the reports around as and when.

As most reporting is clyclical (month end, year end, financial year, monthly sales, weekly orders, etc) it's possible to predict the reports you'll need for a particular period and it's possible, using Reporting Services and SharePoint to scheduled the reports to run when you know you'll need them.

The first step is to go to your report;

|

| Simple SSRS Reporting Showing GL Segments |

When you select "Subscribe" you'll be directed to the following web page to select the options for the report;

|

| SSRS Subscription Properties |

- Email (default): You can choose to have a report sent to any email address (for example a distribution list) but you should already remember that only the person who sets up the Subscription will be able to edit it and if they leave and their Active Directory (AD) account is disabled the subscription will automatically stop

- Windows File Share: Select this to choose to have the report sent to a Windows File Share. You can specify your username and password to grant access. Useful under certain circumstances, but I'd recommend switching to a ...

- SharePoint Document Library: We like this one. Again it requires some setting up by your system administrator but once it's there then you get all the nice features of SharePoint (sharing, versioning, security, etc) without the permission problems of Windows File Shares. This is our preferred option for in-house reporting

- Null Delivery Provider: Sometimes it's necessary just to run the report without worrying about the results (triggering caching automatically for example). If that's the case then this is the provider to select.

- Output Format/ Report Contents/ Render Format (Depends on Delivery Extension selected): Here you can select the format you want the report to be saved in. You can (in Sharepoint 2007 with SQL SSRS 2008R2) only select a single format which means if you want the report in multiple formats (for example PDF for archiving, and Excel for working with) you need to create multiple schedules (if you'd like to show Microsoft you'd like to see this changed you can vote for the item on Connect - see here)

- Delivery Event: You can select either; a) When a report snapshot is created, b) On a shared schedule, or c) on a Custom Schedule. You need to decide when you want the report and whether it's important or not if it runs at the *exact* time specified or within a few minutes/ hours. If it absolutely has to run at a specific time then select Custom Schedule

|

| "Delivery Event" Subscription Options* |

- Parameters: Here you select the parameters for your report. Here you'll definitely need the help of the report writers who need to have written the report with scheduling in mind in order for it to work. For example if you have a report which has a Start and End Date then the default values need to be default to, for example, the start and end of last month so that when it's scheduled to run on the 1st of every month the user can just select "defaults" rather than having to hard-code values. With a bit of planning this can work really well (NOTE: The list of parameters includes *all* parameters for the report including ones developers have marked as Hidden - I've raised this as a bug with Microsoft click here)

*- you'll notice, if you squint really hard at the "Shared Schedule" option that we (OK, I) made a mistake when setting these up. The point of shared schedules should be to increase the flexibility of system administrators to juggle the jobs around but make sure they are still available when needed. "Monthly (1st) @ 7am)" isn't exactly flexible, what I should have created is "Monthly (1st) before 8:30" so I'd be able to move the reports around as and when.

Friday, August 31, 2012

Oracle R12 Lot Genealogy and Noetix

If, like me, you work in a process manufacturing* company one of the key things you need to worry about is lot genealogy. Put simply this is the process that a manufacturer uses to determine where the raw ingredients went. When you read about a product recall in the press this is the process the company will have gone through to trace where every product to be recalled went.

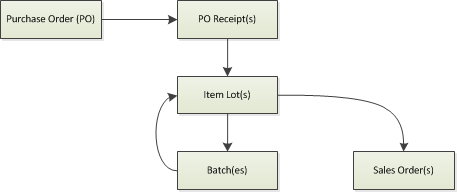

Here's a simple diagram of the process;

As is made (hopefully!) obvious in the diagram the main issue with reporting on Lot Genealogy is recursion. In Release 11 Oracle used to provide a lot genealogy report, it seems they have removed this report in Release 12 although the same information is available via the standard Oracle Forms (although if you have to file reports with the FDA or HMRC it's questionable how well "we've got it on the screen" will go down).

Each step in the above process is logged as an item transaction (amongst a lot of other events). There are four steps to the process;

SELECT ilt.lot_number

FROM invg0_lot_transactions ilt

WHERE 1 = 1

AND ilt.PO_Number = 'XXX'

AND ilt.transaction_type = 'PO Receipt';

Now the first thing you'll notice if you're familiar with the view is that I'm using a "PO Number" column - a column that doesn't exist in the basic view as provided by Noetix. In order to simplify not just Lot Genealogy but reporting in general we have added a number of customisations to this view. These are available as a single file here (via Google Docs). Strictly speaking it's not necessary to add these customisations as we could do it all in the script I'll show you below, but it does make it a great deal easier (for example do you prefer "DECODE( MATTR.TRANSACTION_SOURCE_TYPE_ID, 5, MATTR.Transaction_Source_ID, null)" or just Batch_Id?).

The second point, which batches did lot X go into, is a little more complicated as we are also at this stage looking to exclude batches where the lot was issues incorrectly and then fully returned (using the "WIP Issue" and "WIP Return" transaction types). See below for the SQL;

The third point, which lots did batch X produce, goes back to the simple-style of the first

The key is "WIP Completion". Now this is where it gets a little interesting. With the SQL above we will pick up "Work in Progress" batches. These are where we have a multi-stage manufacturing process - such as granulation and then coating - and need to put the intermediary product on the system. So when the result of granulation is transported for coating it is stored on the system as a new batch and then the batch is emptied and input into the coating process - we could have filtered these out using the "WIP Completion Return" type in the same way we did above with WIP Issue/ WIP Return but the view I took when developing this is that correcting a mistake (as is the case with WIP Issue/ WIP Return) is different from materials passing through a batch as part of a process (WIP Completion). Hope that's clear?

The final part, which lots fulfil a sales order, is probably the simplest piece of SQL yet;

Now we have the four parts of the story we need to work out lot genealogy it seems like it's just a simple matter of adding in a recursive lookup on batches to lots and we're there. And yes - you could do it that way but in my experience what you end up with is the recursion being done in different ways in different reports (for example if we are wanting to know where a raw material went in a report we might want to exclude packaging lots). You then find yourself having to "debug" a problem with a report and spending hours working out what this specific version of log genealogy is doing.

For this reason I have implemented a solution that processes the transactions as they are done and builds a cache of lot genealogy information (with a few bits of useful reporting information to prevent some of the more obvious lookups).

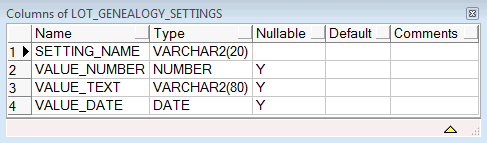

The first step is to build the tables. The three tables I'm using are;

The creation script is available here (via Google Docs).

NOTE: You'll need to insert a single record to be picked up as the minimum transaction number (use -1) see the code for the package below to determine the values!

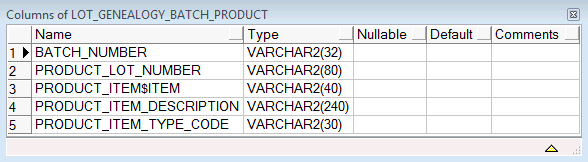

The columns for the Lot_Genealogy_Batch_Product are;

The creation script is available here (via Google Docs).

You'll notice when you look at the SQL that this table is indexed in order to speed up the retrieval of data. The time taken will depend on the amount of data you have but with the indexs (on this and the following table) the time taken to process eight months of data for us was about 3 minutes (that's approximately 571,000 lot transactions).

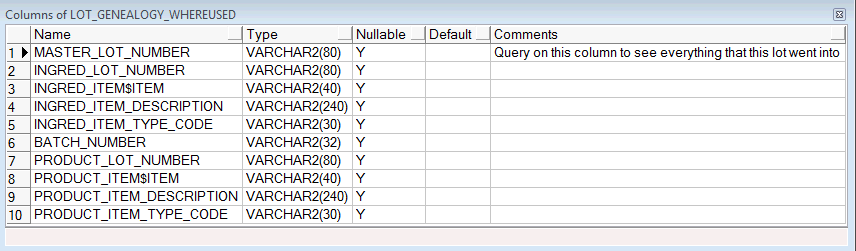

The final table (and the most important one) is Lot_Genealogy_WhereUsed, it's columns are;

The creation script for this table is available here (via Google Docs).

You'll notice that I'm creating all the tables in the NOETIX_SYS schema. The reason for this is fairly simple; as this package (and process) is dependant on Noetix and the Noetix Views will be rebuilt periodically I think it's better to have the creation script for the *package* (below) to be part of Noetix Regenerate; this way it gets automatically tested each time we do a build.

Now here's the script to create the package header;

That's a little simple, here's the body;

Now you'll see that I've included a fair amount of comments on what the code is doing and also I've left in (but commented out) some of the debug lines I've been using. you can also tell my clear preference for using FOR ... LOOP instead of SELECT ... INTO statements (mainly so I don't have a temporary variable lying around or end up with a variable called v_Temp).

I hope this is fairly self-explanatory what it's doing. Let me know in the comments below if you have any questions or if anything is not clear.

*- Process Manufacturing means you take ingredients and you feed them into a process and make something as opposed to Discrete Manufacturing where you take parts and assemble them into something. The key difference is that you don't know how much (exactly) you will make in Process Manufacturing whereas for Discrete if you have all the parts of a car you will make precisely one car. Clear?

Here's a simple diagram of the process;

|

| Simple Lot Genealogy |

As is made (hopefully!) obvious in the diagram the main issue with reporting on Lot Genealogy is recursion. In Release 11 Oracle used to provide a lot genealogy report, it seems they have removed this report in Release 12 although the same information is available via the standard Oracle Forms (although if you have to file reports with the FDA or HMRC it's questionable how well "we've got it on the screen" will go down).

Each step in the above process is logged as an item transaction (amongst a lot of other events). There are four steps to the process;

- Which lots were created as a result of purchase order W?

- Which batches did lot X go into?

- Which lots did batch Y go into?

- Which lots fulfilled sales order Z?

SELECT ilt.lot_number

FROM invg0_lot_transactions ilt

WHERE 1 = 1

AND ilt.PO_Number = 'XXX'

AND ilt.transaction_type = 'PO Receipt';

Now the first thing you'll notice if you're familiar with the view is that I'm using a "PO Number" column - a column that doesn't exist in the basic view as provided by Noetix. In order to simplify not just Lot Genealogy but reporting in general we have added a number of customisations to this view. These are available as a single file here (via Google Docs). Strictly speaking it's not necessary to add these customisations as we could do it all in the script I'll show you below, but it does make it a great deal easier (for example do you prefer "DECODE( MATTR.TRANSACTION_SOURCE_TYPE_ID, 5, MATTR.Transaction_Source_ID, null)" or just Batch_Id?).

The second point, which batches did lot X go into, is a little more complicated as we are also at this stage looking to exclude batches where the lot was issues incorrectly and then fully returned (using the "WIP Issue" and "WIP Return" transaction types). See below for the SQL;

SELECT ilt.Batch_Number, SUM(ilt.TRANSACTION_QUANTITY)

FROM invg0_lot_transactions ilt

WHERE 1=1

AND ilt.lot_number = 'XXX'

AND ilt.Transaction_Source_Type = 'Job or Schedule'

AND (ilt.transaction_type = 'WIP Issue' OR ilt.Transaction_Type = 'WIP Return')

FROM invg0_lot_transactions ilt

WHERE 1=1

AND ilt.lot_number = 'XXX'

AND ilt.Transaction_Source_Type = 'Job or Schedule'

AND (ilt.transaction_type = 'WIP Issue' OR ilt.Transaction_Type = 'WIP Return')

GROUP BY ilt.batch_number

HAVING SUM(ilt.TRANSACTION_QUANTITY) < 0

HAVING SUM(ilt.TRANSACTION_QUANTITY) < 0

The third point, which lots did batch X produce, goes back to the simple-style of the first

SELECT itd.LOT_NUMBER

FROM invg0_lot_transactions itd

WHERE 1=1

AND itd.transaction_type = 'WIP Completion'

AND itd.Transaction_Source_Type = 'Job or Schedule'

AND itd.Batch_Number = 'XXX'

FROM invg0_lot_transactions itd

WHERE 1=1

AND itd.transaction_type = 'WIP Completion'

AND itd.Transaction_Source_Type = 'Job or Schedule'

AND itd.Batch_Number = 'XXX'

The key is "WIP Completion". Now this is where it gets a little interesting. With the SQL above we will pick up "Work in Progress" batches. These are where we have a multi-stage manufacturing process - such as granulation and then coating - and need to put the intermediary product on the system. So when the result of granulation is transported for coating it is stored on the system as a new batch and then the batch is emptied and input into the coating process - we could have filtered these out using the "WIP Completion Return" type in the same way we did above with WIP Issue/ WIP Return but the view I took when developing this is that correcting a mistake (as is the case with WIP Issue/ WIP Return) is different from materials passing through a batch as part of a process (WIP Completion). Hope that's clear?

The final part, which lots fulfil a sales order, is probably the simplest piece of SQL yet;

SELECT itd.LOT_NUMBER

FROM invg0_lot_transactions itd

WHERE 1=1

AND itd.Sales_Order_Number = 'XXX'

WHERE 1=1

AND itd.Sales_Order_Number = 'XXX'

Now we have the four parts of the story we need to work out lot genealogy it seems like it's just a simple matter of adding in a recursive lookup on batches to lots and we're there. And yes - you could do it that way but in my experience what you end up with is the recursion being done in different ways in different reports (for example if we are wanting to know where a raw material went in a report we might want to exclude packaging lots). You then find yourself having to "debug" a problem with a report and spending hours working out what this specific version of log genealogy is doing.

For this reason I have implemented a solution that processes the transactions as they are done and builds a cache of lot genealogy information (with a few bits of useful reporting information to prevent some of the more obvious lookups).

The first step is to build the tables. The three tables I'm using are;

- Lot_Genealogy_Settings (this just holds a setting to record the last transaction processed),

- Lot_Genealogy_WhereUsed (this holds the genealogy information from a "where used" perspective), and

- Lot_Genealogy_Batch_Product (this holds a list of the products for each batch)

|

| Table Description: Lot_Genealogy_Settings |

The creation script is available here (via Google Docs).

NOTE: You'll need to insert a single record to be picked up as the minimum transaction number (use -1) see the code for the package below to determine the values!

The columns for the Lot_Genealogy_Batch_Product are;

|

| Table Description: Lot_Genealogy_Batch_Product |

You'll notice when you look at the SQL that this table is indexed in order to speed up the retrieval of data. The time taken will depend on the amount of data you have but with the indexs (on this and the following table) the time taken to process eight months of data for us was about 3 minutes (that's approximately 571,000 lot transactions).

The final table (and the most important one) is Lot_Genealogy_WhereUsed, it's columns are;

|

| Table Description: Lot_Genealogy_WhereUsed |

You'll notice that I'm creating all the tables in the NOETIX_SYS schema. The reason for this is fairly simple; as this package (and process) is dependant on Noetix and the Noetix Views will be rebuilt periodically I think it's better to have the creation script for the *package* (below) to be part of Noetix Regenerate; this way it gets automatically tested each time we do a build.

Now here's the script to create the package header;

create or replace package lot_genealogy is

procedure doUpdate;

end lot_genealogy;

procedure doUpdate;

end lot_genealogy;

That's a little simple, here's the body;

create or replace package body lot_genealogy is

procedure doUpdate as

v_Exists BOOLEAN;

v_MaxTransactionNumber NUMBER;

BEGIN

-- SECTION 0100: Remove Any Existing Records From The Cache

/*DELETE FROM NOETIX_SYS.Lot_Genealogy_WhereUsed;

DELETE FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT;

COMMIT;

UPDATE NOETIX_SYS.Lot_Genealogy_Settings LGS

SET LGS.VALUE_NUMBER = -1

WHERE LGS.Setting_Name = 'MAX_TRANS_NO';*/

FOR v_Check IN (SELECT VALUE_NUMBER

FROM NOETIX_SYS.Lot_Genealogy_Settings LGS

WHERE LGS.Setting_Name = 'MAX_TRANS_NO') LOOP

v_MaxTransactionNumber := v_Check.Value_Number;

END LOOP;

-- SECTION 1000: Process The Lot Transaction Records From INVG0_Lot_Transactions

FOR v_Transaction IN (SELECT ilt.Transaction_Number,

ilt.batch_number,

ilt.transaction_quantity,

ilt.lot_number,

ilt.transaction_type,

ilt.ITEM$Item,

ilt.Item_Description,

ilt.Item_Type_Code

FROM INVG0_LOT_TRANSACTIONS ilt

WHERE ilt.Transaction_Source_Type =

'Job or Schedule'

AND (ilt.transaction_type = 'WIP Issue' OR

--ilt.Transaction_Type = 'WIP Return' OR

ilt.Transaction_Type = 'WIP Completion')

AND ilt.Transaction_Number >

v_MaxTransactionNumber

--AND ilt.lot_number IN ('166130', '035598', '166127')

/*AND ilt.lot_number IN

('029996',

'165507WIP',

'165507C1',

'165507',

'165583',

'167866WIP',

'167866',

'167951')*/

--AND ilt.transaction_number <= 2053180 -- For testing, about 6,000 records

ORDER BY ilt.Transaction_Number) LOOP

-- SECTION 1100: Process WIP Completion Transaction

-- NOTE: This section answers the question "What lots did batch X produce?"

IF (v_Transaction.Transaction_Type = 'WIP Completion') THEN

-- If we have already created records for this batch then we can update them with the new

-- product UNLESS we already have a product for this batch

UPDATE NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

SET LGI.PRODUCT_LOT_NUMBER = v_Transaction.Lot_Number,

LGI.Product_Item$item = v_Transaction.Item$item,

LGI.Product_Item_Description = v_Transaction.Item_Description,

LGI.Product_Item_Type_Code = v_Transaction.Item_Type_Code

WHERE LGI.BATCH_NUMBER = v_Transaction.Batch_Number

AND (LGI.PRODUCT_LOT_NUMBER IS NULL OR -- ... we haven't updated the product lot before

LGI.PRODUCT_LOT_NUMBER = v_Transaction.Lot_Number); -- ... we have but this is the same

IF SQL%ROWCOUNT = 0 THEN

-- Nothing's been updated. New record?

-- Insert the new record for each batch number where it already exists in the LG table (providing

-- it doesn't already exist)

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT DISTINCT LGI.Master_Lot_Number, -- Mater_Lot_Number

LGI.INGRED_LOT_NUMBER, -- Ingred_Lot_Number

LGI.INGRED_ITEM$ITEM, -- INGRED_ITEM$ITEM

LGI.INGRED_ITEM_DESCRIPTION, -- INGRED_ITEM_DESCRIPTION

LGI.INGRED_ITEM_TYPE_CODE, -- INGRED_ITEM_TYPE_CODE

LGI.BATCH_NUMBER,

v_Transaction.Lot_Number, -- Product_Lot_Number

v_Transaction.ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Transaction.ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Transaction.ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.BATCH_NUMBER = v_Transaction.Batch_Number

AND NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI1

WHERE LGI1.MASTER_LOT_NUMBER = LGI.Master_Lot_Number

AND LGI1.Ingred_LOT_NUMBER = LGI.ingred_Lot_Number

AND LGI1.BATCH_NUMBER = LGI.Batch_Number

AND LGI1.PRODUCT_LOT_NUMBER =

v_Transaction.Lot_Number);

END IF;

-- In case this batch appears in another transaction later let's record

-- what the completed products were

INSERT INTO NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT

SELECT v_Transaction.Batch_Number, -- Batch_Number,

v_Transaction.Lot_Number, -- Product_Lot_Number

v_Transaction.ITEM$Item, -- PRODUCT_ITEM$ITEM

v_Transaction.Item_Description, -- Product_Item_Description

v_Transaction.Item_Type_Code -- Product_Item_Type_Code

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS. LGBP

WHERE LGBP.BATCH_NUMBER = v_Transaction.Batch_Number

AND LGBP.Product_Lot_Number = v_Transaction.Lot_Number);

ELSIF (v_Transaction.Transaction_Type = 'WIP Issue') THEN

v_Exists := False;

-- Was this issue to the Batch reversed?

FOR v_Check IN (SELECT 'X'

FROM INVG0_LOT_TRANSACTIONS ilt

WHERE ilt.Transaction_Source_Type =

'Job or Schedule'

AND ilt.Transaction_Type = 'WIP Return'

AND ilt.batch_number = v_Transaction.Batch_Number

and ilt.TRANSACTION_QUANTITY =

(v_Transaction.Transaction_Quantity * -1)

and ilt.LOT_NUMBER = v_Transaction.Lot_Number) LOOP

v_Exists := True; -- Yes it was (WIP Issued in error)

END LOOP;

-- If the WIP Issue wasn't reversed ...

IF (NOT v_Exists) THEN

-- Get the batch product(s) (if we can) otherwise return NULL

FOR v_Product IN (SELECT LGBP.PRODUCT_LOT_NUMBER,

LGBP.PRODUCT_ITEM$ITEM,

LGBP.PRODUCT_ITEM_DESCRIPTION,

LGBP.PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT LGBP

WHERE LGBP.BATCH_NUMBER =

v_Transaction.Batch_Number

UNION

SELECT NULL, NULL, NULL, NULL

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT LGBP

WHERE LGBP.BATCH_NUMBER =

v_Transaction.Batch_Number)) LOOP

-- For each batch product create a LG record (if it doesn't already exist)

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT v_Transaction.Lot_Number, -- Master_Lot_Number

v_Transaction.Lot_Number, -- Ingred_Lot_Number

v_Transaction.Item$item, -- INGRED_ITEM$ITEM

v_Transaction.Item_Description, -- INGRED_ITEM_DESCRIPTION

v_Transaction.Item_Type_Code, -- INGRED_ITEM_TYPE_CODE

v_Transaction.Batch_Number, -- Batch_Number

v_Product.Product_Lot_Number, -- Product_Lot_Number

v_Product.PRODUCT_ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Product.PRODUCT_ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Product.PRODUCT_ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.MASTER_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI.Ingred_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI.Batch_Number = v_Transaction.Batch_Number

AND (v_Product.Product_Lot_Number IS NULL AND

LGI.PRODUCT_LOT_NUMBER IS NULL OR

v_Product.Product_Lot_Number =

LGI.PRODUCT_LOT_NUMBER));

-- ... and add to existing master lot numbers with the same product lot

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT DISTINCT LGI.MASTER_LOT_NUMBER, -- Master_Lot_Number

v_Transaction.Lot_Number, -- Ingred_Lot_Number

v_Transaction.Item$item, -- INGRED_ITEM$ITEM

v_Transaction.Item_Description, -- INGRED_ITEM_DESCRIPTION

v_Transaction.Item_Type_Code, -- INGRED_ITEM_TYPE_CODE

v_Transaction.Batch_Number, -- Batch_Number

v_Product.Product_Lot_Number, -- Product_Lot_Number

v_Product.PRODUCT_ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Product.PRODUCT_ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Product.PRODUCT_ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.Product_Lot_Number = v_Transaction.Lot_Number

AND NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI1

WHERE LGI1.MASTER_LOT_NUMBER = LGI.MASTER_LOT_NUMBER

AND LGI1.Ingred_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI1.Batch_Number = v_Transaction.Batch_Number

AND (v_Product.Product_Lot_Number IS NULL AND

LGI1.PRODUCT_LOT_NUMBER IS NULL OR

v_Product.Product_Lot_Number =

LGI1.PRODUCT_LOT_NUMBER));

END LOOP;

END IF;

END IF;

-- Record the transaction number we've just processed so we don't process it again

v_MaxTransactionNumber := v_Transaction.Transaction_Number;

END LOOP;

-- Record the last transaction number we processed so we can go from there next time

UPDATE NOETIX_SYS.Lot_Genealogy_Settings LGS

SET LGS.VALUE_NUMBER = v_MaxTransactionNumber

WHERE LGS.Setting_Name = 'MAX_TRANS_NO';

COMMIT;

end doUpdate;

end lot_genealogy;

procedure doUpdate as

v_Exists BOOLEAN;

v_MaxTransactionNumber NUMBER;

BEGIN

-- SECTION 0100: Remove Any Existing Records From The Cache

/*DELETE FROM NOETIX_SYS.Lot_Genealogy_WhereUsed;

DELETE FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT;

COMMIT;

UPDATE NOETIX_SYS.Lot_Genealogy_Settings LGS

SET LGS.VALUE_NUMBER = -1

WHERE LGS.Setting_Name = 'MAX_TRANS_NO';*/

FOR v_Check IN (SELECT VALUE_NUMBER

FROM NOETIX_SYS.Lot_Genealogy_Settings LGS

WHERE LGS.Setting_Name = 'MAX_TRANS_NO') LOOP

v_MaxTransactionNumber := v_Check.Value_Number;

END LOOP;

-- SECTION 1000: Process The Lot Transaction Records From INVG0_Lot_Transactions

FOR v_Transaction IN (SELECT ilt.Transaction_Number,

ilt.batch_number,

ilt.transaction_quantity,

ilt.lot_number,

ilt.transaction_type,

ilt.ITEM$Item,

ilt.Item_Description,

ilt.Item_Type_Code

FROM INVG0_LOT_TRANSACTIONS ilt

WHERE ilt.Transaction_Source_Type =

'Job or Schedule'

AND (ilt.transaction_type = 'WIP Issue' OR

--ilt.Transaction_Type = 'WIP Return' OR

ilt.Transaction_Type = 'WIP Completion')

AND ilt.Transaction_Number >

v_MaxTransactionNumber

--AND ilt.lot_number IN ('166130', '035598', '166127')

/*AND ilt.lot_number IN

('029996',

'165507WIP',

'165507C1',

'165507',

'165583',

'167866WIP',

'167866',

'167951')*/

--AND ilt.transaction_number <= 2053180 -- For testing, about 6,000 records

ORDER BY ilt.Transaction_Number) LOOP

-- SECTION 1100: Process WIP Completion Transaction

-- NOTE: This section answers the question "What lots did batch X produce?"

IF (v_Transaction.Transaction_Type = 'WIP Completion') THEN

-- If we have already created records for this batch then we can update them with the new

-- product UNLESS we already have a product for this batch

UPDATE NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

SET LGI.PRODUCT_LOT_NUMBER = v_Transaction.Lot_Number,

LGI.Product_Item$item = v_Transaction.Item$item,

LGI.Product_Item_Description = v_Transaction.Item_Description,

LGI.Product_Item_Type_Code = v_Transaction.Item_Type_Code

WHERE LGI.BATCH_NUMBER = v_Transaction.Batch_Number

AND (LGI.PRODUCT_LOT_NUMBER IS NULL OR -- ... we haven't updated the product lot before

LGI.PRODUCT_LOT_NUMBER = v_Transaction.Lot_Number); -- ... we have but this is the same

IF SQL%ROWCOUNT = 0 THEN

-- Nothing's been updated. New record?

-- Insert the new record for each batch number where it already exists in the LG table (providing

-- it doesn't already exist)

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT DISTINCT LGI.Master_Lot_Number, -- Mater_Lot_Number

LGI.INGRED_LOT_NUMBER, -- Ingred_Lot_Number

LGI.INGRED_ITEM$ITEM, -- INGRED_ITEM$ITEM

LGI.INGRED_ITEM_DESCRIPTION, -- INGRED_ITEM_DESCRIPTION

LGI.INGRED_ITEM_TYPE_CODE, -- INGRED_ITEM_TYPE_CODE

LGI.BATCH_NUMBER,

v_Transaction.Lot_Number, -- Product_Lot_Number

v_Transaction.ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Transaction.ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Transaction.ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.BATCH_NUMBER = v_Transaction.Batch_Number

AND NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI1

WHERE LGI1.MASTER_LOT_NUMBER = LGI.Master_Lot_Number

AND LGI1.Ingred_LOT_NUMBER = LGI.ingred_Lot_Number

AND LGI1.BATCH_NUMBER = LGI.Batch_Number

AND LGI1.PRODUCT_LOT_NUMBER =

v_Transaction.Lot_Number);

END IF;

-- In case this batch appears in another transaction later let's record

-- what the completed products were

INSERT INTO NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT

SELECT v_Transaction.Batch_Number, -- Batch_Number,

v_Transaction.Lot_Number, -- Product_Lot_Number

v_Transaction.ITEM$Item, -- PRODUCT_ITEM$ITEM

v_Transaction.Item_Description, -- Product_Item_Description

v_Transaction.Item_Type_Code -- Product_Item_Type_Code

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS. LGBP

WHERE LGBP.BATCH_NUMBER = v_Transaction.Batch_Number

AND LGBP.Product_Lot_Number = v_Transaction.Lot_Number);

ELSIF (v_Transaction.Transaction_Type = 'WIP Issue') THEN

v_Exists := False;

-- Was this issue to the Batch reversed?

FOR v_Check IN (SELECT 'X'

FROM INVG0_LOT_TRANSACTIONS ilt

WHERE ilt.Transaction_Source_Type =

'Job or Schedule'

AND ilt.Transaction_Type = 'WIP Return'

AND ilt.batch_number = v_Transaction.Batch_Number

and ilt.TRANSACTION_QUANTITY =

(v_Transaction.Transaction_Quantity * -1)

and ilt.LOT_NUMBER = v_Transaction.Lot_Number) LOOP

v_Exists := True; -- Yes it was (WIP Issued in error)

END LOOP;

-- If the WIP Issue wasn't reversed ...

IF (NOT v_Exists) THEN

-- Get the batch product(s) (if we can) otherwise return NULL

FOR v_Product IN (SELECT LGBP.PRODUCT_LOT_NUMBER,

LGBP.PRODUCT_ITEM$ITEM,

LGBP.PRODUCT_ITEM_DESCRIPTION,

LGBP.PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT LGBP

WHERE LGBP.BATCH_NUMBER =

v_Transaction.Batch_Number

UNION

SELECT NULL, NULL, NULL, NULL

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.LOT_GENEALOGY_BATCH_PRODUCT LGBP

WHERE LGBP.BATCH_NUMBER =

v_Transaction.Batch_Number)) LOOP

-- For each batch product create a LG record (if it doesn't already exist)

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT v_Transaction.Lot_Number, -- Master_Lot_Number

v_Transaction.Lot_Number, -- Ingred_Lot_Number

v_Transaction.Item$item, -- INGRED_ITEM$ITEM

v_Transaction.Item_Description, -- INGRED_ITEM_DESCRIPTION

v_Transaction.Item_Type_Code, -- INGRED_ITEM_TYPE_CODE

v_Transaction.Batch_Number, -- Batch_Number

v_Product.Product_Lot_Number, -- Product_Lot_Number

v_Product.PRODUCT_ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Product.PRODUCT_ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Product.PRODUCT_ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM DUAL

WHERE NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.MASTER_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI.Ingred_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI.Batch_Number = v_Transaction.Batch_Number

AND (v_Product.Product_Lot_Number IS NULL AND

LGI.PRODUCT_LOT_NUMBER IS NULL OR

v_Product.Product_Lot_Number =

LGI.PRODUCT_LOT_NUMBER));

-- ... and add to existing master lot numbers with the same product lot

INSERT INTO NOETIX_SYS.Lot_Genealogy_WhereUsed

SELECT DISTINCT LGI.MASTER_LOT_NUMBER, -- Master_Lot_Number

v_Transaction.Lot_Number, -- Ingred_Lot_Number

v_Transaction.Item$item, -- INGRED_ITEM$ITEM

v_Transaction.Item_Description, -- INGRED_ITEM_DESCRIPTION

v_Transaction.Item_Type_Code, -- INGRED_ITEM_TYPE_CODE

v_Transaction.Batch_Number, -- Batch_Number

v_Product.Product_Lot_Number, -- Product_Lot_Number

v_Product.PRODUCT_ITEM$ITEM, -- PRODUCT_ITEM$ITEM

v_Product.PRODUCT_ITEM_DESCRIPTION, -- PRODUCT_ITEM_DESCRIPTION

v_Product.PRODUCT_ITEM_TYPE_CODE -- PRODUCT_ITEM_TYPE_CODE

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI

WHERE LGI.Product_Lot_Number = v_Transaction.Lot_Number

AND NOT EXISTS

(SELECT 1

FROM NOETIX_SYS.Lot_Genealogy_WhereUsed LGI1

WHERE LGI1.MASTER_LOT_NUMBER = LGI.MASTER_LOT_NUMBER

AND LGI1.Ingred_LOT_NUMBER =

v_Transaction.Lot_Number

AND LGI1.Batch_Number = v_Transaction.Batch_Number

AND (v_Product.Product_Lot_Number IS NULL AND

LGI1.PRODUCT_LOT_NUMBER IS NULL OR

v_Product.Product_Lot_Number =

LGI1.PRODUCT_LOT_NUMBER));

END LOOP;

END IF;

END IF;

-- Record the transaction number we've just processed so we don't process it again

v_MaxTransactionNumber := v_Transaction.Transaction_Number;

END LOOP;

-- Record the last transaction number we processed so we can go from there next time

UPDATE NOETIX_SYS.Lot_Genealogy_Settings LGS

SET LGS.VALUE_NUMBER = v_MaxTransactionNumber

WHERE LGS.Setting_Name = 'MAX_TRANS_NO';

COMMIT;

end doUpdate;

end lot_genealogy;

Now you'll see that I've included a fair amount of comments on what the code is doing and also I've left in (but commented out) some of the debug lines I've been using. you can also tell my clear preference for using FOR ... LOOP instead of SELECT ... INTO statements (mainly so I don't have a temporary variable lying around or end up with a variable called v_Temp).

I hope this is fairly self-explanatory what it's doing. Let me know in the comments below if you have any questions or if anything is not clear.

*- Process Manufacturing means you take ingredients and you feed them into a process and make something as opposed to Discrete Manufacturing where you take parts and assemble them into something. The key difference is that you don't know how much (exactly) you will make in Process Manufacturing whereas for Discrete if you have all the parts of a car you will make precisely one car. Clear?

Thursday, August 23, 2012

PL/SQL: Using R12 Item Open Interface Tables

I'm sure we won't be the only company to need to do a batch update of all the existing Items (in INV.MTL_SYSTEM_ITEMS_B) so I thought I'd share this. Basically using the interface tables and Concurrent Request allows you to make updates to the existing reports in a controlled (and Oracle Approved) way.

I'm going to talk about doing an UPDATE but CREATE will work in pretty much the same way (for various reasons I'm not going to look at DELETE and I imagine - even if oracle supported it - most people would be in the same boat).

The first step is to identify the open interface table;

The columns from the MTL_System_Items_Interface table are listed at the every end of this post (just for your reference). The critical columns that have to have values in order for the update to work are;

Now if you want to insert records into the interface table it's probably best to use a SELECT as part of the SQL (i.e. have the rows you want to change listed in another table).

The SQL updates details on the item master from a table called PD_Item_Mst stored in a remove database across a database link (REMOTE_DATABASE). This updating flexfields in the item master (attributes 23,25,22, and 11). Here's the sample SQL;

INSERT INTO INV.MTL_SYSTEM_ITEMS_INTERFACE

(ORGANIZATION_ID,

PROCESS_FLAG,

ITEM_NUMBER,

TRANSACTION_TYPE,

ATTRIBUTE23,

ATTRIBUTE25,

ATTRIBUTE22,

ATTRIBUTE15)

SELECT 1, -- organization_id

1, -- process_flag

item_no, -- item_number

'UPDATE', -- transaction_type

cd_flag, -- attribute23

in_house, -- attribute25

inv_class, -- attribute22

DECODE(no_colours, 'INT', 98, 'CO', 97, 'FG', 99) -- attribute15

FROM pd_item_mst@REMOTE_DATABASE

Once you've got the items loaded into the interface table you then need to log into Oracle e-Business Suite and perform the import.

Once you have logged in you'll need the "Inventory" reponsiiblity in order to make the changes. Once you have switched to the "Inventory" responsibility select Items then Import and finally "Import Items";

If, like us, you have multiple Organizations you will see the dialog above and have to pick which Organisation you wish to work with. When you've picked an Organization you will then be presented with the Concurrent Request screen;

Make sure you have changed the Create or Update Option so that it is 1 for Inserting Items, and 2 for Updating Items. When you're ready click "Submit".

When completed check the INV.MTL_SYSTEM_ITEMS_INTERFACE table to see if any lines are remaining and are unprocessed. If any are unprocessed (erroring), then check in the INV.MTL_INTERFACE_ERRORS table for the reason.

Key to this working is that the ORG_ID in the lines is the same as the Concurrent Req (sounds obvious, but there is aflag which seems to indicate it will run for all orgs, but doesn’t). Also that the Transaction type in the lines matches the option in the concurrent request i.e. both Update, or both Create.

Hope you found this useful ...

List of Columns on the INV.MTL_System_Items_Interface table;

I'm going to talk about doing an UPDATE but CREATE will work in pretty much the same way (for various reasons I'm not going to look at DELETE and I imagine - even if oracle supported it - most people would be in the same boat).

The first step is to identify the open interface table;

- INV.MTL_System_items_Interface

The columns from the MTL_System_Items_Interface table are listed at the every end of this post (just for your reference). The critical columns that have to have values in order for the update to work are;

Organization_Id

Process_Flag (must be 1)

Item_Number (of you can use SEGMENT1)

Transaction_Type (must be either UPDATE or CREATE)Now if you want to insert records into the interface table it's probably best to use a SELECT as part of the SQL (i.e. have the rows you want to change listed in another table).

The SQL updates details on the item master from a table called PD_Item_Mst stored in a remove database across a database link (REMOTE_DATABASE). This updating flexfields in the item master (attributes 23,25,22, and 11). Here's the sample SQL;

INSERT INTO INV.MTL_SYSTEM_ITEMS_INTERFACE

(ORGANIZATION_ID,

PROCESS_FLAG,

ITEM_NUMBER,

TRANSACTION_TYPE,

ATTRIBUTE23,

ATTRIBUTE25,

ATTRIBUTE22,

ATTRIBUTE15)

SELECT 1, -- organization_id

1, -- process_flag

item_no, -- item_number

'UPDATE', -- transaction_type

cd_flag, -- attribute23

in_house, -- attribute25

inv_class, -- attribute22

DECODE(no_colours, 'INT', 98, 'CO', 97, 'FG', 99) -- attribute15

FROM pd_item_mst@REMOTE_DATABASE

Once you've got the items loaded into the interface table you then need to log into Oracle e-Business Suite and perform the import.

Once you have logged in you'll need the "Inventory" reponsiiblity in order to make the changes. Once you have switched to the "Inventory" responsibility select Items then Import and finally "Import Items";

| |||

| Importing Items |

|

| Importing Items Concurrent Request |

When completed check the INV.MTL_SYSTEM_ITEMS_INTERFACE table to see if any lines are remaining and are unprocessed. If any are unprocessed (erroring), then check in the INV.MTL_INTERFACE_ERRORS table for the reason.

Key to this working is that the ORG_ID in the lines is the same as the Concurrent Req (sounds obvious, but there is aflag which seems to indicate it will run for all orgs, but doesn’t). Also that the Transaction type in the lines matches the option in the concurrent request i.e. both Update, or both Create.

Hope you found this useful ...

List of Columns on the INV.MTL_System_Items_Interface table;

SQL> DESC INV.MTL_System_items_Interface

Name Type Nullable Default Comments

------------------------------ -------------- -------- ------- --------

INVENTORY_ITEM_ID NUMBER Y

ORGANIZATION_ID NUMBER Y

LAST_UPDATE_DATE DATE Y

LAST_UPDATED_BY NUMBER Y

CREATION_DATE DATE Y

CREATED_BY NUMBER Y

LAST_UPDATE_LOGIN NUMBER Y

SUMMARY_FLAG VARCHAR2(1) Y

ENABLED_FLAG VARCHAR2(1) Y

START_DATE_ACTIVE DATE Y

END_DATE_ACTIVE DATE Y

DESCRIPTION VARCHAR2(240) Y

BUYER_ID NUMBER Y

ACCOUNTING_RULE_ID NUMBER Y

INVOICING_RULE_ID NUMBER Y

SEGMENT1 VARCHAR2(40) Y

SEGMENT2 VARCHAR2(40) Y

SEGMENT3 VARCHAR2(40) Y

SEGMENT4 VARCHAR2(40) Y

SEGMENT5 VARCHAR2(40) Y

SEGMENT6 VARCHAR2(40) Y

SEGMENT7 VARCHAR2(40) Y

SEGMENT8 VARCHAR2(40) Y

SEGMENT9 VARCHAR2(40) Y

SEGMENT10 VARCHAR2(40) Y

SEGMENT11 VARCHAR2(40) Y

SEGMENT12 VARCHAR2(40) Y

SEGMENT13 VARCHAR2(40) Y

SEGMENT14 VARCHAR2(40) Y

SEGMENT15 VARCHAR2(40) Y

SEGMENT16 VARCHAR2(40) Y

SEGMENT17 VARCHAR2(40) Y

SEGMENT18 VARCHAR2(40) Y

SEGMENT19 VARCHAR2(40) Y

SEGMENT20 VARCHAR2(40) Y

ATTRIBUTE_CATEGORY VARCHAR2(30) Y

ATTRIBUTE1 VARCHAR2(240) Y

ATTRIBUTE2 VARCHAR2(240) Y

ATTRIBUTE3 VARCHAR2(240) Y

ATTRIBUTE4 VARCHAR2(240) Y

ATTRIBUTE5 VARCHAR2(240) Y

ATTRIBUTE6 VARCHAR2(240) Y

ATTRIBUTE7 VARCHAR2(240) Y

ATTRIBUTE8 VARCHAR2(240) Y

ATTRIBUTE9 VARCHAR2(240) Y

ATTRIBUTE10 VARCHAR2(240) Y

ATTRIBUTE11 VARCHAR2(240) Y

ATTRIBUTE12 VARCHAR2(240) Y

ATTRIBUTE13 VARCHAR2(240) Y

ATTRIBUTE14 VARCHAR2(240) Y

ATTRIBUTE15 VARCHAR2(240) Y

PURCHASING_ITEM_FLAG VARCHAR2(1) Y

SHIPPABLE_ITEM_FLAG VARCHAR2(1) Y

CUSTOMER_ORDER_FLAG VARCHAR2(1) Y

INTERNAL_ORDER_FLAG VARCHAR2(1) Y

SERVICE_ITEM_FLAG VARCHAR2(1) Y

INVENTORY_ITEM_FLAG VARCHAR2(1) Y

ENG_ITEM_FLAG VARCHAR2(1) Y

INVENTORY_ASSET_FLAG VARCHAR2(1) Y

PURCHASING_ENABLED_FLAG VARCHAR2(1) Y

CUSTOMER_ORDER_ENABLED_FLAG VARCHAR2(1) Y

INTERNAL_ORDER_ENABLED_FLAG VARCHAR2(1) Y

SO_TRANSACTIONS_FLAG VARCHAR2(1) Y

MTL_TRANSACTIONS_ENABLED_FLAG VARCHAR2(1) Y

STOCK_ENABLED_FLAG VARCHAR2(1) Y

BOM_ENABLED_FLAG VARCHAR2(1) Y

BUILD_IN_WIP_FLAG VARCHAR2(1) Y

REVISION_QTY_CONTROL_CODE NUMBER Y

ITEM_CATALOG_GROUP_ID NUMBER Y

CATALOG_STATUS_FLAG VARCHAR2(1) Y

RETURNABLE_FLAG VARCHAR2(1) Y

DEFAULT_SHIPPING_ORG NUMBER Y

COLLATERAL_FLAG VARCHAR2(1) Y

TAXABLE_FLAG VARCHAR2(1) Y

QTY_RCV_EXCEPTION_CODE VARCHAR2(25) Y

ALLOW_ITEM_DESC_UPDATE_FLAG VARCHAR2(1) Y

INSPECTION_REQUIRED_FLAG VARCHAR2(1) Y

RECEIPT_REQUIRED_FLAG VARCHAR2(1) Y

MARKET_PRICE NUMBER Y

HAZARD_CLASS_ID NUMBER Y

RFQ_REQUIRED_FLAG VARCHAR2(1) Y

QTY_RCV_TOLERANCE NUMBER Y

LIST_PRICE_PER_UNIT NUMBER Y

UN_NUMBER_ID NUMBER Y

PRICE_TOLERANCE_PERCENT NUMBER Y

ASSET_CATEGORY_ID NUMBER Y

ROUNDING_FACTOR NUMBER Y

UNIT_OF_ISSUE VARCHAR2(25) Y

ENFORCE_SHIP_TO_LOCATION_CODE VARCHAR2(25) Y

ALLOW_SUBSTITUTE_RECEIPTS_FLAG VARCHAR2(1) Y

ALLOW_UNORDERED_RECEIPTS_FLAG VARCHAR2(1) Y

ALLOW_EXPRESS_DELIVERY_FLAG VARCHAR2(1) Y

DAYS_EARLY_RECEIPT_ALLOWED NUMBER Y

DAYS_LATE_RECEIPT_ALLOWED NUMBER Y

RECEIPT_DAYS_EXCEPTION_CODE VARCHAR2(25) Y

RECEIVING_ROUTING_ID NUMBER Y

INVOICE_CLOSE_TOLERANCE NUMBER Y

RECEIVE_CLOSE_TOLERANCE NUMBER Y

AUTO_LOT_ALPHA_PREFIX VARCHAR2(30) Y

START_AUTO_LOT_NUMBER VARCHAR2(30) Y

LOT_CONTROL_CODE NUMBER Y

SHELF_LIFE_CODE NUMBER Y

SHELF_LIFE_DAYS NUMBER Y

SERIAL_NUMBER_CONTROL_CODE NUMBER Y

START_AUTO_SERIAL_NUMBER VARCHAR2(30) Y

AUTO_SERIAL_ALPHA_PREFIX VARCHAR2(30) Y

SOURCE_TYPE NUMBER Y

SOURCE_ORGANIZATION_ID NUMBER Y

SOURCE_SUBINVENTORY VARCHAR2(10) Y

EXPENSE_ACCOUNT NUMBER Y

ENCUMBRANCE_ACCOUNT NUMBER Y

RESTRICT_SUBINVENTORIES_CODE NUMBER Y

UNIT_WEIGHT NUMBER Y

WEIGHT_UOM_CODE VARCHAR2(3) Y

VOLUME_UOM_CODE VARCHAR2(3) Y

UNIT_VOLUME NUMBER Y

RESTRICT_LOCATORS_CODE NUMBER Y

LOCATION_CONTROL_CODE NUMBER Y

SHRINKAGE_RATE NUMBER Y

ACCEPTABLE_EARLY_DAYS NUMBER Y

PLANNING_TIME_FENCE_CODE NUMBER Y

DEMAND_TIME_FENCE_CODE NUMBER Y

LEAD_TIME_LOT_SIZE NUMBER Y

STD_LOT_SIZE NUMBER Y

CUM_MANUFACTURING_LEAD_TIME NUMBER Y

OVERRUN_PERCENTAGE NUMBER Y

MRP_CALCULATE_ATP_FLAG VARCHAR2(1) Y

ACCEPTABLE_RATE_INCREASE NUMBER Y

ACCEPTABLE_RATE_DECREASE NUMBER Y

CUMULATIVE_TOTAL_LEAD_TIME NUMBER Y

PLANNING_TIME_FENCE_DAYS NUMBER Y

DEMAND_TIME_FENCE_DAYS NUMBER Y

END_ASSEMBLY_PEGGING_FLAG VARCHAR2(1) Y

REPETITIVE_PLANNING_FLAG VARCHAR2(1) Y

PLANNING_EXCEPTION_SET VARCHAR2(10) Y

BOM_ITEM_TYPE NUMBER Y

PICK_COMPONENTS_FLAG VARCHAR2(1) Y

REPLENISH_TO_ORDER_FLAG VARCHAR2(1) Y

BASE_ITEM_ID NUMBER Y

ATP_COMPONENTS_FLAG VARCHAR2(1) Y

ATP_FLAG VARCHAR2(1) Y

FIXED_LEAD_TIME NUMBER Y

VARIABLE_LEAD_TIME NUMBER Y

WIP_SUPPLY_LOCATOR_ID NUMBER Y

WIP_SUPPLY_TYPE NUMBER Y

WIP_SUPPLY_SUBINVENTORY VARCHAR2(10) Y

PRIMARY_UOM_CODE VARCHAR2(3) Y

PRIMARY_UNIT_OF_MEASURE VARCHAR2(25) Y

ALLOWED_UNITS_LOOKUP_CODE NUMBER Y

COST_OF_SALES_ACCOUNT NUMBER Y

SALES_ACCOUNT NUMBER Y

DEFAULT_INCLUDE_IN_ROLLUP_FLAG VARCHAR2(1) Y

INVENTORY_ITEM_STATUS_CODE VARCHAR2(10) Y

INVENTORY_PLANNING_CODE NUMBER Y

PLANNER_CODE VARCHAR2(10) Y

PLANNING_MAKE_BUY_CODE NUMBER Y

FIXED_LOT_MULTIPLIER NUMBER Y

ROUNDING_CONTROL_TYPE NUMBER Y

CARRYING_COST NUMBER Y

POSTPROCESSING_LEAD_TIME NUMBER Y

PREPROCESSING_LEAD_TIME NUMBER Y

FULL_LEAD_TIME NUMBER Y

ORDER_COST NUMBER Y

MRP_SAFETY_STOCK_PERCENT NUMBER Y

MRP_SAFETY_STOCK_CODE NUMBER Y

MIN_MINMAX_QUANTITY NUMBER Y

MAX_MINMAX_QUANTITY NUMBER Y

MINIMUM_ORDER_QUANTITY NUMBER Y

FIXED_ORDER_QUANTITY NUMBER Y

FIXED_DAYS_SUPPLY NUMBER Y

MAXIMUM_ORDER_QUANTITY NUMBER Y

ATP_RULE_ID NUMBER Y

PICKING_RULE_ID NUMBER Y

RESERVABLE_TYPE NUMBER Y

POSITIVE_MEASUREMENT_ERROR NUMBER Y

NEGATIVE_MEASUREMENT_ERROR NUMBER Y

ENGINEERING_ECN_CODE VARCHAR2(50) Y

ENGINEERING_ITEM_ID NUMBER Y

ENGINEERING_DATE DATE Y

SERVICE_STARTING_DELAY NUMBER Y

VENDOR_WARRANTY_FLAG VARCHAR2(1) Y

SERVICEABLE_COMPONENT_FLAG VARCHAR2(1) Y

SERVICEABLE_PRODUCT_FLAG VARCHAR2(1) Y

BASE_WARRANTY_SERVICE_ID NUMBER Y

PAYMENT_TERMS_ID NUMBER Y

PREVENTIVE_MAINTENANCE_FLAG VARCHAR2(1) Y

PRIMARY_SPECIALIST_ID NUMBER Y

SECONDARY_SPECIALIST_ID NUMBER Y

SERVICEABLE_ITEM_CLASS_ID NUMBER Y

TIME_BILLABLE_FLAG VARCHAR2(1) Y

MATERIAL_BILLABLE_FLAG VARCHAR2(30) Y

EXPENSE_BILLABLE_FLAG VARCHAR2(1) Y

PRORATE_SERVICE_FLAG VARCHAR2(1) Y

COVERAGE_SCHEDULE_ID NUMBER Y

SERVICE_DURATION_PERIOD_CODE VARCHAR2(10) Y

SERVICE_DURATION NUMBER Y

WARRANTY_VENDOR_ID NUMBER Y

MAX_WARRANTY_AMOUNT NUMBER Y

RESPONSE_TIME_PERIOD_CODE VARCHAR2(30) Y

RESPONSE_TIME_VALUE NUMBER Y

NEW_REVISION_CODE VARCHAR2(30) Y

INVOICEABLE_ITEM_FLAG VARCHAR2(1) Y

TAX_CODE VARCHAR2(50) Y

INVOICE_ENABLED_FLAG VARCHAR2(1) Y

MUST_USE_APPROVED_VENDOR_FLAG VARCHAR2(1) Y

REQUEST_ID NUMBER Y

PROGRAM_APPLICATION_ID NUMBER Y

PROGRAM_ID NUMBER Y

PROGRAM_UPDATE_DATE DATE Y

OUTSIDE_OPERATION_FLAG VARCHAR2(1) Y

OUTSIDE_OPERATION_UOM_TYPE VARCHAR2(25) Y

SAFETY_STOCK_BUCKET_DAYS NUMBER Y

AUTO_REDUCE_MPS NUMBER(22) Y

COSTING_ENABLED_FLAG VARCHAR2(1) Y

CYCLE_COUNT_ENABLED_FLAG VARCHAR2(1) Y

DEMAND_SOURCE_LINE VARCHAR2(30) Y

COPY_ITEM_ID NUMBER Y

SET_ID VARCHAR2(10) Y

REVISION VARCHAR2(3) Y

AUTO_CREATED_CONFIG_FLAG VARCHAR2(1) Y

ITEM_TYPE VARCHAR2(30) Y

MODEL_CONFIG_CLAUSE_NAME VARCHAR2(10) Y

SHIP_MODEL_COMPLETE_FLAG VARCHAR2(1) Y

MRP_PLANNING_CODE NUMBER Y

RETURN_INSPECTION_REQUIREMENT NUMBER Y

DEMAND_SOURCE_TYPE NUMBER Y

DEMAND_SOURCE_HEADER_ID NUMBER Y

TRANSACTION_ID NUMBER Y

PROCESS_FLAG NUMBER Y

ORGANIZATION_CODE VARCHAR2(3) Y

ITEM_NUMBER VARCHAR2(700) Y

COPY_ITEM_NUMBER VARCHAR2(81) Y

TEMPLATE_ID NUMBER Y

TEMPLATE_NAME VARCHAR2(30) Y

COPY_ORGANIZATION_ID NUMBER Y

COPY_ORGANIZATION_CODE VARCHAR2(3) Y

ATO_FORECAST_CONTROL NUMBER Y

TRANSACTION_TYPE VARCHAR2(10) Y

MATERIAL_COST NUMBER Y

MATERIAL_SUB_ELEM VARCHAR2(10) Y

MATERIAL_OH_RATE NUMBER Y

MATERIAL_OH_SUB_ELEM VARCHAR2(10) Y

MATERIAL_SUB_ELEM_ID NUMBER Y

MATERIAL_OH_SUB_ELEM_ID NUMBER Y

AUTO_REL_TIME_FENCE_CODE NUMBER Y

AUTO_REL_TIME_FENCE_DAYS NUMBER Y

CONTAINER_ITEM_FLAG VARCHAR2(1) Y

VEHICLE_ITEM_FLAG VARCHAR2(1) Y

MAXIMUM_LOAD_WEIGHT NUMBER Y

MINIMUM_FILL_PERCENT NUMBER Y

CONTAINER_TYPE_CODE VARCHAR2(30) Y

INTERNAL_VOLUME NUMBER Y

SET_PROCESS_ID NUMBER 0

CHECK_SHORTAGES_FLAG VARCHAR2(1) Y

RELEASE_TIME_FENCE_CODE NUMBER Y

RELEASE_TIME_FENCE_DAYS NUMBER Y

WH_UPDATE_DATE DATE Y

PRODUCT_FAMILY_ITEM_ID NUMBER Y

PURCHASING_TAX_CODE VARCHAR2(50) Y

OVERCOMPLETION_TOLERANCE_TYPE NUMBER Y

OVERCOMPLETION_TOLERANCE_VALUE NUMBER Y

EFFECTIVITY_CONTROL NUMBER Y

GLOBAL_ATTRIBUTE_CATEGORY VARCHAR2(150) Y

GLOBAL_ATTRIBUTE1 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE2 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE3 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE4 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE5 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE6 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE7 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE8 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE9 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE10 VARCHAR2(150) Y

OVER_SHIPMENT_TOLERANCE NUMBER Y

UNDER_SHIPMENT_TOLERANCE NUMBER Y

OVER_RETURN_TOLERANCE NUMBER Y

UNDER_RETURN_TOLERANCE NUMBER Y

EQUIPMENT_TYPE NUMBER Y

RECOVERED_PART_DISP_CODE VARCHAR2(30) Y

DEFECT_TRACKING_ON_FLAG VARCHAR2(1) Y

USAGE_ITEM_FLAG VARCHAR2(1) Y

EVENT_FLAG VARCHAR2(1) Y

ELECTRONIC_FLAG VARCHAR2(1) Y

DOWNLOADABLE_FLAG VARCHAR2(1) Y

VOL_DISCOUNT_EXEMPT_FLAG VARCHAR2(1) Y

COUPON_EXEMPT_FLAG VARCHAR2(1) Y

COMMS_NL_TRACKABLE_FLAG VARCHAR2(1) Y

ASSET_CREATION_CODE VARCHAR2(30) Y

COMMS_ACTIVATION_REQD_FLAG VARCHAR2(1) Y

ORDERABLE_ON_WEB_FLAG VARCHAR2(1) Y

BACK_ORDERABLE_FLAG VARCHAR2(1) Y

WEB_STATUS VARCHAR2(30) Y

INDIVISIBLE_FLAG VARCHAR2(1) Y

LONG_DESCRIPTION VARCHAR2(4000) Y

DIMENSION_UOM_CODE VARCHAR2(3) Y

UNIT_LENGTH NUMBER Y

UNIT_WIDTH NUMBER Y

UNIT_HEIGHT NUMBER Y

BULK_PICKED_FLAG VARCHAR2(1) Y

LOT_STATUS_ENABLED VARCHAR2(1) Y

DEFAULT_LOT_STATUS_ID NUMBER Y

SERIAL_STATUS_ENABLED VARCHAR2(1) Y

DEFAULT_SERIAL_STATUS_ID NUMBER Y

LOT_SPLIT_ENABLED VARCHAR2(1) Y

LOT_MERGE_ENABLED VARCHAR2(1) Y

INVENTORY_CARRY_PENALTY NUMBER Y

OPERATION_SLACK_PENALTY NUMBER Y

FINANCING_ALLOWED_FLAG VARCHAR2(1) Y

EAM_ITEM_TYPE NUMBER Y

EAM_ACTIVITY_TYPE_CODE VARCHAR2(30) Y

EAM_ACTIVITY_CAUSE_CODE VARCHAR2(30) Y

EAM_ACT_NOTIFICATION_FLAG VARCHAR2(1) Y

EAM_ACT_SHUTDOWN_STATUS VARCHAR2(30) Y

DUAL_UOM_CONTROL NUMBER Y

SECONDARY_UOM_CODE VARCHAR2(3) Y

DUAL_UOM_DEVIATION_HIGH NUMBER Y

DUAL_UOM_DEVIATION_LOW NUMBER Y

CONTRACT_ITEM_TYPE_CODE VARCHAR2(30) Y

SUBSCRIPTION_DEPEND_FLAG VARCHAR2(1) Y

SERV_REQ_ENABLED_CODE VARCHAR2(30) Y

SERV_BILLING_ENABLED_FLAG VARCHAR2(1) Y

SERV_IMPORTANCE_LEVEL NUMBER Y

PLANNED_INV_POINT_FLAG VARCHAR2(1) Y

LOT_TRANSLATE_ENABLED VARCHAR2(1) Y

DEFAULT_SO_SOURCE_TYPE VARCHAR2(30) Y

CREATE_SUPPLY_FLAG VARCHAR2(1) Y

SUBSTITUTION_WINDOW_CODE NUMBER Y

SUBSTITUTION_WINDOW_DAYS NUMBER Y

IB_ITEM_INSTANCE_CLASS VARCHAR2(30) Y

CONFIG_MODEL_TYPE VARCHAR2(30) Y

LOT_SUBSTITUTION_ENABLED VARCHAR2(1) Y

MINIMUM_LICENSE_QUANTITY NUMBER Y

EAM_ACTIVITY_SOURCE_CODE VARCHAR2(30) Y

LIFECYCLE_ID NUMBER Y

CURRENT_PHASE_ID NUMBER Y

TRACKING_QUANTITY_IND VARCHAR2(30) Y

ONT_PRICING_QTY_SOURCE VARCHAR2(30) Y

SECONDARY_DEFAULT_IND VARCHAR2(30) Y

VMI_MINIMUM_UNITS NUMBER Y

VMI_MINIMUM_DAYS NUMBER Y

VMI_MAXIMUM_UNITS NUMBER Y

VMI_MAXIMUM_DAYS NUMBER Y

VMI_FIXED_ORDER_QUANTITY NUMBER Y

SO_AUTHORIZATION_FLAG NUMBER Y

CONSIGNED_FLAG NUMBER Y

ASN_AUTOEXPIRE_FLAG NUMBER Y

VMI_FORECAST_TYPE NUMBER Y

FORECAST_HORIZON NUMBER Y

EXCLUDE_FROM_BUDGET_FLAG NUMBER Y

DAYS_TGT_INV_SUPPLY NUMBER Y

DAYS_TGT_INV_WINDOW NUMBER Y

DAYS_MAX_INV_SUPPLY NUMBER Y

DAYS_MAX_INV_WINDOW NUMBER Y

DRP_PLANNED_FLAG NUMBER Y

CRITICAL_COMPONENT_FLAG NUMBER Y

CONTINOUS_TRANSFER NUMBER Y

CONVERGENCE NUMBER Y

DIVERGENCE NUMBER Y

CONFIG_ORGS VARCHAR2(30) Y

CONFIG_MATCH VARCHAR2(30) Y

ATTRIBUTE16 VARCHAR2(240) Y

ATTRIBUTE17 VARCHAR2(240) Y

ATTRIBUTE18 VARCHAR2(240) Y

ATTRIBUTE19 VARCHAR2(240) Y

ATTRIBUTE20 VARCHAR2(240) Y

ATTRIBUTE21 VARCHAR2(240) Y

ATTRIBUTE22 VARCHAR2(240) Y

ATTRIBUTE23 VARCHAR2(240) Y

ATTRIBUTE24 VARCHAR2(240) Y

ATTRIBUTE25 VARCHAR2(240) Y

ATTRIBUTE26 VARCHAR2(240) Y

ATTRIBUTE27 VARCHAR2(240) Y

ATTRIBUTE28 VARCHAR2(240) Y

ATTRIBUTE29 VARCHAR2(240) Y

ATTRIBUTE30 VARCHAR2(240) Y

CAS_NUMBER VARCHAR2(30) Y

CHILD_LOT_FLAG VARCHAR2(1) Y

CHILD_LOT_PREFIX VARCHAR2(30) Y

CHILD_LOT_STARTING_NUMBER NUMBER Y

CHILD_LOT_VALIDATION_FLAG VARCHAR2(1) Y

COPY_LOT_ATTRIBUTE_FLAG VARCHAR2(1) Y

DEFAULT_GRADE VARCHAR2(150) Y

EXPIRATION_ACTION_CODE VARCHAR2(32) Y

EXPIRATION_ACTION_INTERVAL NUMBER Y

GRADE_CONTROL_FLAG VARCHAR2(1) Y

HAZARDOUS_MATERIAL_FLAG VARCHAR2(1) Y

HOLD_DAYS NUMBER Y

LOT_DIVISIBLE_FLAG VARCHAR2(1) Y

MATURITY_DAYS NUMBER Y

PARENT_CHILD_GENERATION_FLAG VARCHAR2(1) Y

PROCESS_COSTING_ENABLED_FLAG VARCHAR2(1) Y

PROCESS_EXECUTION_ENABLED_FLAG VARCHAR2(1) Y

PROCESS_QUALITY_ENABLED_FLAG VARCHAR2(1) Y

PROCESS_SUPPLY_LOCATOR_ID NUMBER Y

PROCESS_SUPPLY_SUBINVENTORY VARCHAR2(10) Y

PROCESS_YIELD_LOCATOR_ID NUMBER Y

PROCESS_YIELD_SUBINVENTORY VARCHAR2(10) Y

RECIPE_ENABLED_FLAG VARCHAR2(1) Y

RETEST_INTERVAL NUMBER Y

CHARGE_PERIODICITY_CODE VARCHAR2(3) Y

REPAIR_LEADTIME NUMBER Y

REPAIR_YIELD NUMBER Y

PREPOSITION_POINT VARCHAR2(1) Y

REPAIR_PROGRAM NUMBER Y

SUBCONTRACTING_COMPONENT NUMBER Y

OUTSOURCED_ASSEMBLY NUMBER Y

SOURCE_SYSTEM_ID NUMBER Y

SOURCE_SYSTEM_REFERENCE VARCHAR2(255) Y

SOURCE_SYSTEM_REFERENCE_DESC VARCHAR2(240) Y

GLOBAL_TRADE_ITEM_NUMBER VARCHAR2(14) Y

CONFIRM_STATUS VARCHAR2(3) Y

CHANGE_ID NUMBER Y

CHANGE_LINE_ID NUMBER Y

ITEM_CATALOG_GROUP_NAME VARCHAR2(820) Y

REVISION_IMPORT_POLICY VARCHAR2(30) Y

GTIN_DESCRIPTION VARCHAR2(240) Y

INTERFACE_TABLE_UNIQUE_ID NUMBER Y

GDSN_OUTBOUND_ENABLED_FLAG VARCHAR2(1) Y

TRADE_ITEM_DESCRIPTOR VARCHAR2(35) Y

STYLE_ITEM_ID NUMBER Y

STYLE_ITEM_FLAG VARCHAR2(1) Y

STYLE_ITEM_NUMBER VARCHAR2(700) Y

COPY_REVISION_ID NUMBER Y

BUNDLE_ID NUMBER Y

MESSAGE_TIMESTAMP DATE Y

MESSAGE_ID NUMBER Y

OPERATION VARCHAR2(80) Y

TOP_ITEM_FLAG VARCHAR2(1) Y

GPC_CODE VARCHAR2(8) Y

GLOBAL_ATTRIBUTE11 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE12 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE13 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE14 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE15 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE16 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE17 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE18 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE19 VARCHAR2(150) Y

GLOBAL_ATTRIBUTE20 VARCHAR2(150) Y

Name Type Nullable Default Comments

------------------------------ -------------- -------- ------- --------

INVENTORY_ITEM_ID NUMBER Y

ORGANIZATION_ID NUMBER Y

LAST_UPDATE_DATE DATE Y

LAST_UPDATED_BY NUMBER Y

CREATION_DATE DATE Y

CREATED_BY NUMBER Y

LAST_UPDATE_LOGIN NUMBER Y

SUMMARY_FLAG VARCHAR2(1) Y

ENABLED_FLAG VARCHAR2(1) Y

START_DATE_ACTIVE DATE Y

END_DATE_ACTIVE DATE Y

DESCRIPTION VARCHAR2(240) Y

BUYER_ID NUMBER Y

ACCOUNTING_RULE_ID NUMBER Y

INVOICING_RULE_ID NUMBER Y

SEGMENT1 VARCHAR2(40) Y

SEGMENT2 VARCHAR2(40) Y

SEGMENT3 VARCHAR2(40) Y

SEGMENT4 VARCHAR2(40) Y

SEGMENT5 VARCHAR2(40) Y

SEGMENT6 VARCHAR2(40) Y

SEGMENT7 VARCHAR2(40) Y

SEGMENT8 VARCHAR2(40) Y

SEGMENT9 VARCHAR2(40) Y

SEGMENT10 VARCHAR2(40) Y

SEGMENT11 VARCHAR2(40) Y

SEGMENT12 VARCHAR2(40) Y

SEGMENT13 VARCHAR2(40) Y

SEGMENT14 VARCHAR2(40) Y

SEGMENT15 VARCHAR2(40) Y

SEGMENT16 VARCHAR2(40) Y

SEGMENT17 VARCHAR2(40) Y

SEGMENT18 VARCHAR2(40) Y

SEGMENT19 VARCHAR2(40) Y

SEGMENT20 VARCHAR2(40) Y

ATTRIBUTE_CATEGORY VARCHAR2(30) Y

ATTRIBUTE1 VARCHAR2(240) Y

ATTRIBUTE2 VARCHAR2(240) Y

ATTRIBUTE3 VARCHAR2(240) Y

ATTRIBUTE4 VARCHAR2(240) Y

ATTRIBUTE5 VARCHAR2(240) Y

ATTRIBUTE6 VARCHAR2(240) Y

ATTRIBUTE7 VARCHAR2(240) Y

ATTRIBUTE8 VARCHAR2(240) Y

ATTRIBUTE9 VARCHAR2(240) Y

ATTRIBUTE10 VARCHAR2(240) Y

ATTRIBUTE11 VARCHAR2(240) Y

ATTRIBUTE12 VARCHAR2(240) Y

ATTRIBUTE13 VARCHAR2(240) Y

ATTRIBUTE14 VARCHAR2(240) Y

ATTRIBUTE15 VARCHAR2(240) Y

PURCHASING_ITEM_FLAG VARCHAR2(1) Y

SHIPPABLE_ITEM_FLAG VARCHAR2(1) Y

CUSTOMER_ORDER_FLAG VARCHAR2(1) Y

INTERNAL_ORDER_FLAG VARCHAR2(1) Y

SERVICE_ITEM_FLAG VARCHAR2(1) Y

INVENTORY_ITEM_FLAG VARCHAR2(1) Y

ENG_ITEM_FLAG VARCHAR2(1) Y

INVENTORY_ASSET_FLAG VARCHAR2(1) Y

PURCHASING_ENABLED_FLAG VARCHAR2(1) Y

CUSTOMER_ORDER_ENABLED_FLAG VARCHAR2(1) Y

INTERNAL_ORDER_ENABLED_FLAG VARCHAR2(1) Y

SO_TRANSACTIONS_FLAG VARCHAR2(1) Y

MTL_TRANSACTIONS_ENABLED_FLAG VARCHAR2(1) Y

STOCK_ENABLED_FLAG VARCHAR2(1) Y

BOM_ENABLED_FLAG VARCHAR2(1) Y

BUILD_IN_WIP_FLAG VARCHAR2(1) Y

REVISION_QTY_CONTROL_CODE NUMBER Y

ITEM_CATALOG_GROUP_ID NUMBER Y

CATALOG_STATUS_FLAG VARCHAR2(1) Y

RETURNABLE_FLAG VARCHAR2(1) Y

DEFAULT_SHIPPING_ORG NUMBER Y

COLLATERAL_FLAG VARCHAR2(1) Y

TAXABLE_FLAG VARCHAR2(1) Y

QTY_RCV_EXCEPTION_CODE VARCHAR2(25) Y

ALLOW_ITEM_DESC_UPDATE_FLAG VARCHAR2(1) Y

INSPECTION_REQUIRED_FLAG VARCHAR2(1) Y

RECEIPT_REQUIRED_FLAG VARCHAR2(1) Y

MARKET_PRICE NUMBER Y

HAZARD_CLASS_ID NUMBER Y

RFQ_REQUIRED_FLAG VARCHAR2(1) Y

QTY_RCV_TOLERANCE NUMBER Y

LIST_PRICE_PER_UNIT NUMBER Y

UN_NUMBER_ID NUMBER Y

PRICE_TOLERANCE_PERCENT NUMBER Y

ASSET_CATEGORY_ID NUMBER Y

ROUNDING_FACTOR NUMBER Y

UNIT_OF_ISSUE VARCHAR2(25) Y

ENFORCE_SHIP_TO_LOCATION_CODE VARCHAR2(25) Y

ALLOW_SUBSTITUTE_RECEIPTS_FLAG VARCHAR2(1) Y

ALLOW_UNORDERED_RECEIPTS_FLAG VARCHAR2(1) Y

ALLOW_EXPRESS_DELIVERY_FLAG VARCHAR2(1) Y

DAYS_EARLY_RECEIPT_ALLOWED NUMBER Y

DAYS_LATE_RECEIPT_ALLOWED NUMBER Y

RECEIPT_DAYS_EXCEPTION_CODE VARCHAR2(25) Y

RECEIVING_ROUTING_ID NUMBER Y

INVOICE_CLOSE_TOLERANCE NUMBER Y

RECEIVE_CLOSE_TOLERANCE NUMBER Y

AUTO_LOT_ALPHA_PREFIX VARCHAR2(30) Y

START_AUTO_LOT_NUMBER VARCHAR2(30) Y

LOT_CONTROL_CODE NUMBER Y

SHELF_LIFE_CODE NUMBER Y

SHELF_LIFE_DAYS NUMBER Y

SERIAL_NUMBER_CONTROL_CODE NUMBER Y

START_AUTO_SERIAL_NUMBER VARCHAR2(30) Y

AUTO_SERIAL_ALPHA_PREFIX VARCHAR2(30) Y

SOURCE_TYPE NUMBER Y

SOURCE_ORGANIZATION_ID NUMBER Y

SOURCE_SUBINVENTORY VARCHAR2(10) Y

EXPENSE_ACCOUNT NUMBER Y

ENCUMBRANCE_ACCOUNT NUMBER Y

RESTRICT_SUBINVENTORIES_CODE NUMBER Y

UNIT_WEIGHT NUMBER Y

WEIGHT_UOM_CODE VARCHAR2(3) Y

VOLUME_UOM_CODE VARCHAR2(3) Y

UNIT_VOLUME NUMBER Y

RESTRICT_LOCATORS_CODE NUMBER Y

LOCATION_CONTROL_CODE NUMBER Y

SHRINKAGE_RATE NUMBER Y

ACCEPTABLE_EARLY_DAYS NUMBER Y

PLANNING_TIME_FENCE_CODE NUMBER Y

DEMAND_TIME_FENCE_CODE NUMBER Y

LEAD_TIME_LOT_SIZE NUMBER Y

STD_LOT_SIZE NUMBER Y

CUM_MANUFACTURING_LEAD_TIME NUMBER Y

OVERRUN_PERCENTAGE NUMBER Y

MRP_CALCULATE_ATP_FLAG VARCHAR2(1) Y

ACCEPTABLE_RATE_INCREASE NUMBER Y

ACCEPTABLE_RATE_DECREASE NUMBER Y

CUMULATIVE_TOTAL_LEAD_TIME NUMBER Y

PLANNING_TIME_FENCE_DAYS NUMBER Y

DEMAND_TIME_FENCE_DAYS NUMBER Y

END_ASSEMBLY_PEGGING_FLAG VARCHAR2(1) Y

REPETITIVE_PLANNING_FLAG VARCHAR2(1) Y

PLANNING_EXCEPTION_SET VARCHAR2(10) Y

BOM_ITEM_TYPE NUMBER Y

PICK_COMPONENTS_FLAG VARCHAR2(1) Y

REPLENISH_TO_ORDER_FLAG VARCHAR2(1) Y

BASE_ITEM_ID NUMBER Y

ATP_COMPONENTS_FLAG VARCHAR2(1) Y

ATP_FLAG VARCHAR2(1) Y

FIXED_LEAD_TIME NUMBER Y

VARIABLE_LEAD_TIME NUMBER Y

WIP_SUPPLY_LOCATOR_ID NUMBER Y

WIP_SUPPLY_TYPE NUMBER Y

WIP_SUPPLY_SUBINVENTORY VARCHAR2(10) Y

PRIMARY_UOM_CODE VARCHAR2(3) Y

PRIMARY_UNIT_OF_MEASURE VARCHAR2(25) Y

ALLOWED_UNITS_LOOKUP_CODE NUMBER Y

COST_OF_SALES_ACCOUNT NUMBER Y

SALES_ACCOUNT NUMBER Y

DEFAULT_INCLUDE_IN_ROLLUP_FLAG VARCHAR2(1) Y

INVENTORY_ITEM_STATUS_CODE VARCHAR2(10) Y

INVENTORY_PLANNING_CODE NUMBER Y

PLANNER_CODE VARCHAR2(10) Y

PLANNING_MAKE_BUY_CODE NUMBER Y

FIXED_LOT_MULTIPLIER NUMBER Y

ROUNDING_CONTROL_TYPE NUMBER Y

CARRYING_COST NUMBER Y

POSTPROCESSING_LEAD_TIME NUMBER Y

PREPROCESSING_LEAD_TIME NUMBER Y

FULL_LEAD_TIME NUMBER Y

ORDER_COST NUMBER Y

MRP_SAFETY_STOCK_PERCENT NUMBER Y

MRP_SAFETY_STOCK_CODE NUMBER Y

MIN_MINMAX_QUANTITY NUMBER Y

MAX_MINMAX_QUANTITY NUMBER Y

MINIMUM_ORDER_QUANTITY NUMBER Y

FIXED_ORDER_QUANTITY NUMBER Y

FIXED_DAYS_SUPPLY NUMBER Y

MAXIMUM_ORDER_QUANTITY NUMBER Y

ATP_RULE_ID NUMBER Y

PICKING_RULE_ID NUMBER Y

RESERVABLE_TYPE NUMBER Y

POSITIVE_MEASUREMENT_ERROR NUMBER Y

NEGATIVE_MEASUREMENT_ERROR NUMBER Y

ENGINEERING_ECN_CODE VARCHAR2(50) Y

ENGINEERING_ITEM_ID NUMBER Y

ENGINEERING_DATE DATE Y

SERVICE_STARTING_DELAY NUMBER Y

VENDOR_WARRANTY_FLAG VARCHAR2(1) Y

SERVICEABLE_COMPONENT_FLAG VARCHAR2(1) Y

SERVICEABLE_PRODUCT_FLAG VARCHAR2(1) Y

BASE_WARRANTY_SERVICE_ID NUMBER Y

PAYMENT_TERMS_ID NUMBER Y

PREVENTIVE_MAINTENANCE_FLAG VARCHAR2(1) Y

PRIMARY_SPECIALIST_ID NUMBER Y

SECONDARY_SPECIALIST_ID NUMBER Y

SERVICEABLE_ITEM_CLASS_ID NUMBER Y

TIME_BILLABLE_FLAG VARCHAR2(1) Y

MATERIAL_BILLABLE_FLAG VARCHAR2(30) Y

EXPENSE_BILLABLE_FLAG VARCHAR2(1) Y

PRORATE_SERVICE_FLAG VARCHAR2(1) Y

COVERAGE_SCHEDULE_ID NUMBER Y

SERVICE_DURATION_PERIOD_CODE VARCHAR2(10) Y

SERVICE_DURATION NUMBER Y

WARRANTY_VENDOR_ID NUMBER Y

MAX_WARRANTY_AMOUNT NUMBER Y

RESPONSE_TIME_PERIOD_CODE VARCHAR2(30) Y

RESPONSE_TIME_VALUE NUMBER Y

NEW_REVISION_CODE VARCHAR2(30) Y

INVOICEABLE_ITEM_FLAG VARCHAR2(1) Y

TAX_CODE VARCHAR2(50) Y

INVOICE_ENABLED_FLAG VARCHAR2(1) Y

MUST_USE_APPROVED_VENDOR_FLAG VARCHAR2(1) Y

REQUEST_ID NUMBER Y

PROGRAM_APPLICATION_ID NUMBER Y

PROGRAM_ID NUMBER Y

PROGRAM_UPDATE_DATE DATE Y

OUTSIDE_OPERATION_FLAG VARCHAR2(1) Y

OUTSIDE_OPERATION_UOM_TYPE VARCHAR2(25) Y

SAFETY_STOCK_BUCKET_DAYS NUMBER Y

AUTO_REDUCE_MPS NUMBER(22) Y

COSTING_ENABLED_FLAG VARCHAR2(1) Y

CYCLE_COUNT_ENABLED_FLAG VARCHAR2(1) Y

DEMAND_SOURCE_LINE VARCHAR2(30) Y

COPY_ITEM_ID NUMBER Y

SET_ID VARCHAR2(10) Y

REVISION VARCHAR2(3) Y

AUTO_CREATED_CONFIG_FLAG VARCHAR2(1) Y

ITEM_TYPE VARCHAR2(30) Y

MODEL_CONFIG_CLAUSE_NAME VARCHAR2(10) Y

SHIP_MODEL_COMPLETE_FLAG VARCHAR2(1) Y

MRP_PLANNING_CODE NUMBER Y

RETURN_INSPECTION_REQUIREMENT NUMBER Y

DEMAND_SOURCE_TYPE NUMBER Y

DEMAND_SOURCE_HEADER_ID NUMBER Y

TRANSACTION_ID NUMBER Y

PROCESS_FLAG NUMBER Y

ORGANIZATION_CODE VARCHAR2(3) Y

ITEM_NUMBER VARCHAR2(700) Y

COPY_ITEM_NUMBER VARCHAR2(81) Y

TEMPLATE_ID NUMBER Y

TEMPLATE_NAME VARCHAR2(30) Y

COPY_ORGANIZATION_ID NUMBER Y

COPY_ORGANIZATION_CODE VARCHAR2(3) Y

ATO_FORECAST_CONTROL NUMBER Y

TRANSACTION_TYPE VARCHAR2(10) Y

MATERIAL_COST NUMBER Y

MATERIAL_SUB_ELEM VARCHAR2(10) Y

MATERIAL_OH_RATE NUMBER Y

MATERIAL_OH_SUB_ELEM VARCHAR2(10) Y

MATERIAL_SUB_ELEM_ID NUMBER Y

MATERIAL_OH_SUB_ELEM_ID NUMBER Y

AUTO_REL_TIME_FENCE_CODE NUMBER Y

AUTO_REL_TIME_FENCE_DAYS NUMBER Y

CONTAINER_ITEM_FLAG VARCHAR2(1) Y

VEHICLE_ITEM_FLAG VARCHAR2(1) Y

MAXIMUM_LOAD_WEIGHT NUMBER Y

MINIMUM_FILL_PERCENT NUMBER Y

CONTAINER_TYPE_CODE VARCHAR2(30) Y

INTERNAL_VOLUME NUMBER Y

SET_PROCESS_ID NUMBER 0

CHECK_SHORTAGES_FLAG VARCHAR2(1) Y

RELEASE_TIME_FENCE_CODE NUMBER Y

RELEASE_TIME_FENCE_DAYS NUMBER Y

WH_UPDATE_DATE DATE Y

PRODUCT_FAMILY_ITEM_ID NUMBER Y

PURCHASING_TAX_CODE VARCHAR2(50) Y